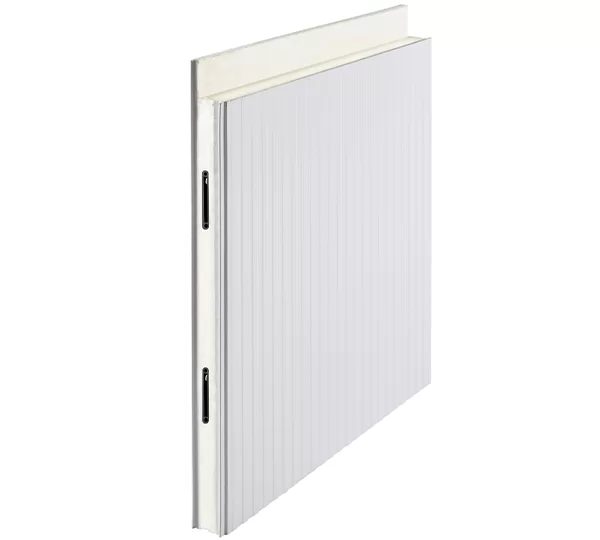

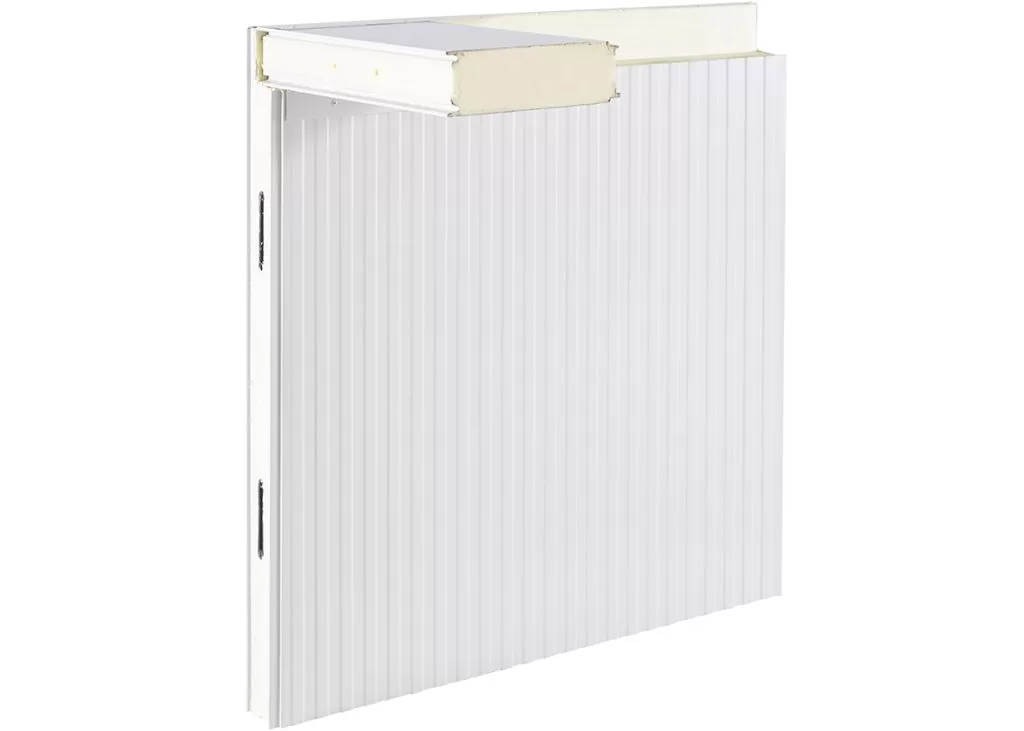

Corrugated Panel

Cold room panels are interlocking panels produced by injecting 42 (+/-2) kg/m³ density polyurethane foam between 0.50mm sheets on both sides. They can also be produced without locks upon request.

Density

Fire Resistant

Soundproofing

Water Resistant

Heat Insulation

Easy Installation

CORRUGATED PANEL GENERAL INFORMATION

Cold room panels are interlocking panels produced by injecting 42 (+/-2) kg/m³ density polyurethane foam between 0.50 mm sheets on both surfaces. They can also be produced without locks upon request.

Panel surface material options include POLY, PVC, Cr-NI, and GALVANIZED sheets. Panel thicknesses range from 50 to 200 mm, with a width of 1110 mm. Panel lengths can be produced up to 12800 mm depending on the shape of the room. The panels’ surface is smooth, hygienic, and easy to clean.

The panels have a special design that prevents heat loss with their accessories. Panels are kept in a 600-ton press for a minimum of 30 minutes and a maximum of 90 minutes until their reaction is complete according to their thickness. During production, a 50-micron surface protection film covers the panels. The panels’ joints are at a maximum level, and heat loss is at a minimum level. Therefore, material savings can be achieved in consumables. They are produced according to the standard B2 flame retardancy class, and production can be made according to the B1 flame retardancy class upon request.

| FEATURES | VALUES |

|---|---|

| Panel Width (cm) | 30 – 40 – 50 – 111 |

| Panel Thickness (mm) | 50 – 60 – 80 – 100 – 120 – 150 – 180 – 200 |

| Panel Density | 40±2 kg/m³ |

| Sheet Coating Types | Polyester – PVC – CrNi |

| Colour | RAL 9002 |

| Pattern | Notched – Straight |

| Insulation | Polyurethane |

| Sheet Thickness (mm) | 0,50 mm |

| FEATURES | VALUES |

|---|---|

| Yield Strength of Sheet Surface (fct) | min. 220N/mm² |

| Tensile Strength of Panel | min. 0,018 Mpa |

| High Temperature Transverse Tensile Module | min. 0,04 MPa |

| Core Material Shear Strength (fcv) | min. 0,11 Mpa |

| Core Material Shear Modulus (G) | min. 2 MPa |

| Core Material Compressive Strength (σ10) | min. 0,09 Mpa |

| Bending Moment Capacity and Rigidity – Flat (Mu) | min. 2,3 kNm/m |

| Bending Moment Capacity and Rigidity – Reverse (Mu) | min. 2 kNm/m |

| Torsional Stress Straight (σw) | 115 MPa |

| Torsional Stress Reverse (σw) | 100 MPa |

| Bending Moment Capacity on a Central Support – Straight | 2,95 kNm/m |

| Bending Moment Capacity on a Central Support – Inverse | 3 kNm/m |

| Torsional Stress Capacity on a Central Support – Straight | 133 MPa |

| Torsional Stress Capacity on a Central Support – Reverse | 118 MPa |

| PUR Thermal Conductivity Value (ʎ) | max. 0,022 W/mK |

| Dimensional Stability | Level DS(TH) 11 |

| Inflammability Class (TS-EN 13501-1) | C-s2,d0 |

| Özellikler | Değerler |

|---|---|

| Thickness | ± %4 |

| Length | ± 10 mm |

| Width | ± 2 mm |

| Deviation from Miter | ± 5 mm |